Sacler with Band Seater

Introduction to the Sacler with Band Seater

The sacler with band seater is an innovative tool that combines advanced technology with practical functionality, enabling users to streamline various processes across multiple industries, including printing, packaging, and manufacturing. This device is designed to efficiently handle a range of tasks, primarily focusing on the secure attachment of banding materials to products. Its design allows for quick adjustments and versatility, ensuring that it can accommodate diverse application requirements and product types.

Fundamentally, the sacler operates by integrating a band seater mechanism that applies cohesive materials around items, creating a secure and stable bond. This method is particularly significant in packaging, where it contributes to protecting products during transportation and storage. The banding process helps in organizing and grouping products, thereby enhancing the overall efficiency of supply chain management. Furthermore, the sacler with band seater can be utilized for aesthetic purposes, as the banding can improve the visual appeal of packaged goods, setting them apart in the marketplace.

An essential attribute of the sacler is its user-friendly interface; it is designed to ensure that operators can quickly learn how to utilize the tool effectively. By offering adjustable settings and easy maintenance options, the sacler facilitates optimal performance across various operational contexts. As industries become increasingly competitive, the adoption of such innovative solutions becomes critical for enhancing productivity and reducing costs. Overall, the sacler with band seater provides a significant advantage by merging functionality with ease of use, thereby promoting better workflow and efficiency in logistics and manufacturing environments.

How to Use the Sacler with Band Seater Effectively

Using the Sacler with a Band Seater requires a systematic approach to achieve optimal results. Begin by gathering all necessary materials, including the Sacler, Band Seater, and the bands you intend to use. Ensure that the workspace is clean and organized to facilitate a smoother workflow. Preparation of materials is crucial, so check that all components are free from defects.

Once your materials are ready, set up the Sacler and Band Seater according to the manufacturer’s specifications. Position the Sacler securely on a stable surface to prevent any movement during operation. It is advisable to place the Band Seater adjacent to the Sacler to minimize the distance required for transferring materials between the two devices.

Before commencing operations, familiarize yourself with the control mechanisms of both devices. The Sacler often has specific settings to accommodate different band sizes or materials. Adjust the tension settings on the Band Seater accordingly, ensuring they match the requirements of your task. It is essential to review the operational guidelines provided by the manufacturers to avoid any errors that could lead to suboptimal results or potential damage to the instruments.

As you work with the Sacler and Band Seater, maintain a consistent pace to enhance efficiency. Pay attention to the bands’ alignment when using the Band Seater, as improper alignment may hinder performance. Regular checks for any inconsistencies or errors during the process will allow you to make real-time adjustments, ensuring quality outputs.

Finally, after completing your tasks, perform routine maintenance on both the Sacler and Band Seater. Cleaning the devices and checking for any wear or damage will prolong their lifespan and maintain their performance. Following these steps will enable you to use the Sacler with Band Seater effectively, optimizing your overall workflow.

Benefits of the Sacler with Band Seater

The incorporation of the sacler with band seater into industrial operations yields numerous benefits, significantly enhancing effectiveness and productivity. One of the most notable advantages is improved efficiency. This sophisticated machinery streamlines the process of sealing and packaging, allowing items to be prepared at a much faster rate than manual methods. As a result, businesses experience expedited workflow, leading to increased output capacity within a shorter time frame.

In addition to efficiency, the sacler with band seater also offers enhanced output quality. The precision engineering of the equipment ensures that seals are applied uniformly and securely, thereby minimizing the chances of leakage or product spoilage. Higher-quality output not only satisfies customer demands but also bolsters a company’s reputation in the market. Reliable results are crucial, particularly in industries where product integrity is paramount.

Versatility is another compelling benefit. The sacler with band seater can accommodate a wide variety of packaging materials and sizes, making it suitable for different applications across various sectors. Whether packaging food products or pharmaceuticals, this equipment adapts seamlessly to meet diverse demands. Furthermore, its configuration allows for easy adjustments, enabling operators to switch between tasks without significant downtime.

Employing the sacler with band seater also leads to substantial time and resource savings. By automating key stages of the packaging process, companies can allocate their workforce to other critical areas, ultimately driving more productive use of labor. This not only reduces operational costs but also enhances overall profitability. Given these extensive benefits, it is evident that integrating the sacler with band seater can transform business operations, positioning organizations for long-term success.

Top 10 Reasons to Buy from Sirecks Enterprises

When considering the acquisition of a sacler with band seater, customers encounter numerous options in the market. However, Sirecks Enterprises stands out for several compelling reasons that exemplify their commitment to quality and customer satisfaction.

Firstly, product quality is paramount at Sirecks Enterprises. Their saclers with band seater are manufactured with premium materials and the latest technology, ensuring durability and performance. Each product undergoes stringent quality control measures, which translates into reliability for users in various industries.

Secondly, excellent customer service is a hallmark of Sirecks Enterprises. Customers can expect timely responses to inquiries and support through the purchasing process, enhancing the overall buying experience. Their customer service team is knowledgeable and well-trained, ready to assist with any questions regarding the product.

Thirdly, price competitiveness is a significant factor for consumers, and Sirecks Enterprises offers attractive pricing structures. They understand the financial constraints businesses face and strive to provide value without compromising on quality.

Additionally, Sirecks Enterprises stands behind their products with exceptional warranty options. This commitment reassures customers of their investment, as it protects them against potential manufacturing defects and provides peace of mind.

Moreover, technical support is readily available. Should customers encounter any operational issues, Sirecks Enterprise’s technical support team ensures they receive prompt assistance, facilitating minimal disruption to their operations.

Lastly, numerous positive customer reviews highlight the satisfaction of previous buyers. These testimonials underscore the effectiveness and reliability of Sirecks Enterprises’ saclers with band seaters, reinforcing their reputation in the industry.

In conclusion, choosing to purchase a sacler with band seater from Sirecks Enterprises is a decision backed by quality, exceptional service, competitive pricing, robust warranty options, and strong customer support, culminating in a noteworthy investment for any business.

Conclusion and Call to Action

In conclusion, mastering the sacler with band seater is a pivotal skill for professionals in various industries, particularly in manufacturing and packaging sectors. The integration of this equipment not only enhances productivity but also ensures a more streamlined and efficient operational process. Throughout the blog, we have examined the significant advantages offered by the sacler with band seater, including improvements in product protection, cost savings, and overall operational efficiency. By effectively utilizing this tool, businesses can achieve higher standards in packaging quality while maintaining competitive edge.

Choosing Sirecks Enterprises as your trusted supplier for the sacler with band seater further solidifies these benefits. Our commitment to quality, customer satisfaction, and comprehensive support sets us apart in the industry. We provide a variety of models tailored to fit different operational needs, allowing businesses to select the most suitable equipment. Furthermore, our dedicated service team is available to assist with any inquiries, ensuring a smooth integration of the sacler with band seater into your existing processes.

As you consider the advantages and applications of the sacler with band seater for your business, we invite you to explore our product offerings in detail. Visit our website or contact our support team to acquire more information about specific models and solutions tailored to your requirements. We are eager to assist you in enhancing your operational capabilities and achieving remarkable results. Take the first step towards mastering the sacler with band seater—partner with Sirecks Enterprises today!

Top 10 Reasons to Buy from Sirecks Enterprises

When considering the acquisition of a sacler with band seater, customers encounter numerous options in the market. However, Sirecks Enterprises stands out for several compelling reasons that exemplify their commitment to quality and customer satisfaction.

Firstly, product quality is paramount at Sirecks Enterprises. Their saclers with band seater are manufactured with premium materials and the latest technology, ensuring durability and performance. Each product undergoes stringent quality control measures, which translates into reliability for users in various industries.

Secondly, excellent customer service is a hallmark of Sirecks Enterprises. Customers can expect timely responses to inquiries and support through the purchasing process, enhancing the overall buying experience. Their customer service team is knowledgeable and well-trained, ready to assist with any questions regarding the product.

Thirdly, price competitiveness is a significant factor for consumers, and Sirecks Enterprises offers attractive pricing structures. They understand the financial constraints businesses face and strive to provide value without compromising on quality.

Additionally, Sirecks Enterprises stands behind their products with exceptional warranty options. This commitment reassures customers of their investment, as it protects them against potential manufacturing defects and provides peace of mind.

Moreover, technical support is readily available. Should customers encounter any operational issues, Sirecks Enterprise’s technical support team ensures they receive prompt assistance, facilitating minimal disruption to their operations.

Lastly, numerous positive customer reviews highlight the satisfaction of previous buyers. These testimonials underscore the effectiveness and reliability of Sirecks Enterprises’ saclers with band seaters, reinforcing their reputation in the industry.

In conclusion, choosing to purchase a sacler with band seater from Sirecks Enterprises is a decision backed by quality, exceptional service, competitive pricing, robust warranty options, and strong customer support, culminating in a noteworthy investment for any business.

Related Posts

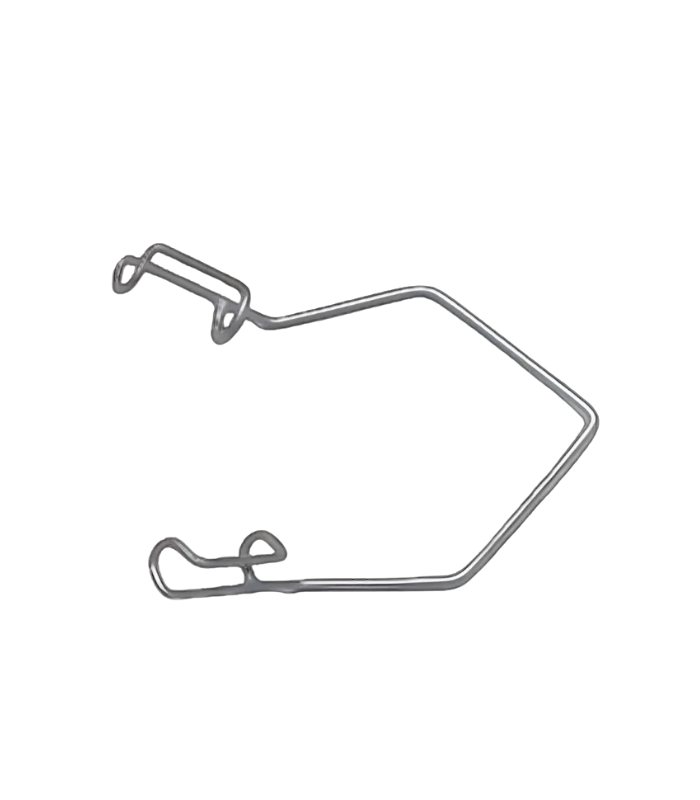

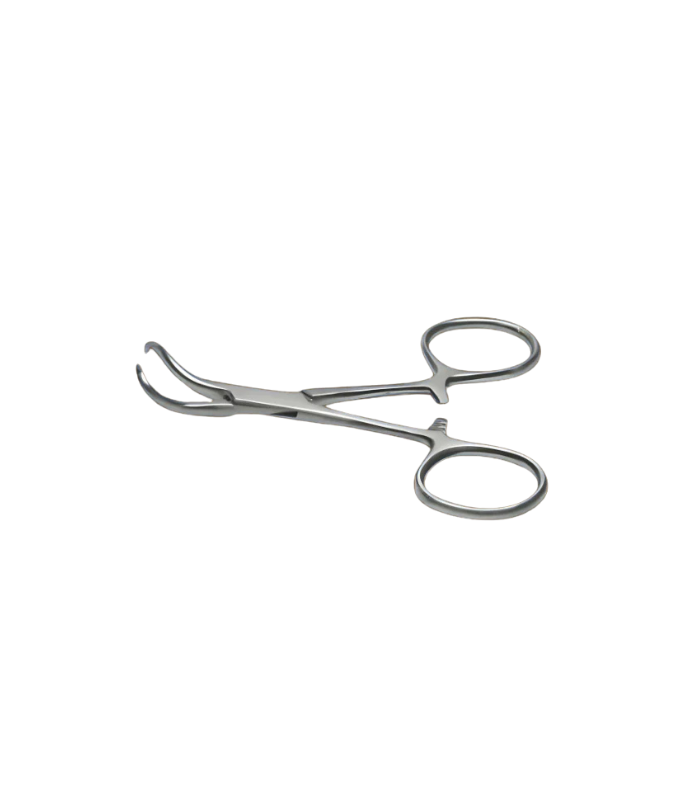

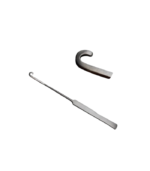

| specification |

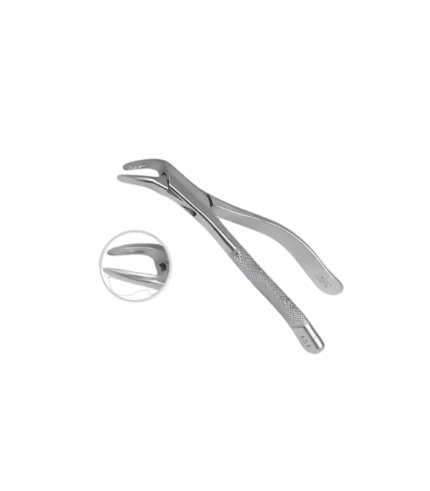

Description: Highly polished finish for aesthetic and corrosion resistance; High Degree of Precision and Flexibility while conducting the Clinical Procedure. |

|---|

Reviews

There are no reviews yet.